On October 1st, 2025, the GRADΞD research project was officially launched under the coordination of Michaël Hinderdael at the Vrije Universiteit Brussel (VUB). With €2.8 million in funding from the Research Foundation – Flanders (FWO) through its Strategic Basic Research (SBO) programme, the four-year project aims to push the boundaries of 3D printing by enabling smarter use of materials inside printed parts. The results could be transformative for sectors such as aerospace, healthcare, and sustainable mobility.

Additive Manufacturing (AM), better known as 3D printing, allows parts to be built layer by layer directly from digital models. It offers unprecedented design freedom, enabling highly complex geometries without the constraints of moulds or cutting tools. Yet, one major limitation persists: most printed parts are made from a single, uniform material. “As a result, engineers often have to make trade-offs”, explains Hinderdael. “You end up choosing one material that performs 'well enough' in all areas, but rarely excels where it matters most. We want to break that compromise.”

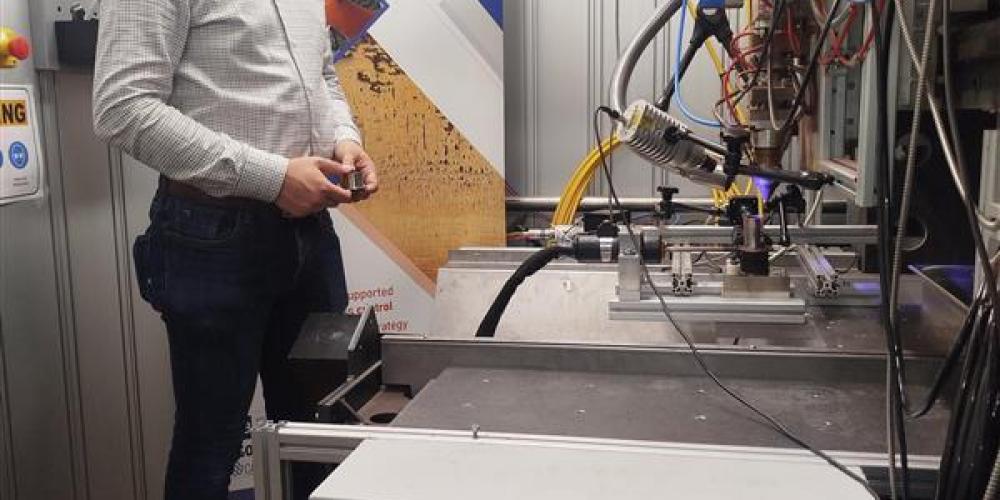

GRADΞD focuses on a cutting-edge 3D printing technique called Directed Energy Deposition (DED). Unlike conventional 3D printing, DED makes it possible to gradually vary material composition within a single part. These so-called Functionally Graded Materials (FGMs) allow engineers to fine-tune strength, wear resistance, heat tolerance or corrosion protection — exactly where it’s needed. However, printing with multiple materials in one go is difficult. It requires precise process control, real-time monitoring, and a deep understanding of how different alloys interact.

The GRADΞD project aims to automate and optimize this complex process. First, advanced simulation tools will identify the ideal printing conditions for selected alloy combinations. Then, sensors will track temperature, geometry, and composition during printing to keep conditions optimal and avoid defects. Once produced, the printed parts will be analyzed and benchmarked against conventional single-material components. In doing so, the project targets a new era of "smart manufacturing", where both shape and material are co-designed and dynamically controlled.

Functionally Graded Materials made through DED could significantly impact various sectors. In aerospace and energy applications, for example, turbine blades can be produced with a tough core and a heat-resistant outer layer, boosting both efficiency and lifespan. In healthcare, the technology enables implants that mimic the gradual stiffness of human bone, which can help reduce rejection and minimize stress between the implant and surrounding tissue. The transport sector stands to benefit as well, with lightweight automotive or aircraft parts that are selectively reinforced where extra strength is needed, without adding unnecessary mass. Even in mould-making for industrial applications, smarter designs can lead to thermally optimized tools with surfaces that resist wear and corrosion, improving both durability and production speed.

The GRADΞD project brings together expertise from VUB (AVRG and B-PHOT research groups) and KU Leuven (SeMPeR and SCALINT). An industrial advisory board, consisting of Flemish companies, supports the project’s valorization strategy. Additional industry partners are welcome to join.

“By combining material intelligence with design freedom, we can create parts that last longer, perform better, and use fewer raw materials — without raising production costs”, says Hinderdael. “That’s a major step forward for the Flemish manufacturing ecosystem.”

The project runs until September 2029. For more information or industry partnership inquiries, please contact project coordinator Michaël Hinderdael via michael.hinderdael@vub.be 02 629 28 07.