Collaborative robots (or cobots) help operators with heavy and repetitive work, wearable exoskeletons provide extra support or strength for ergonomically demanding jobs. In the future, the cooperation between man and machine will become increasingly intimate. The Flanders Make/VUB research lab AugmentX is conducting cutting edge research into this interaction. The lab also advises and guides manufacturing companies that want to introduce robotics in their production.

'The man machine, superhuman being,...' The catchy tune by Kraftwerk is the ideal soundtrack for a visit to the Flanders Make/VUB's AugmentX Research Lab, on floor -1 of Pleinlaan 9. 'We are the robots' could also have been chosen. Scattered across two large basement rooms are robots of all shapes, sizes and colours. Most of them are robotic arms. Such a robot arm is a powerful, movable mechanical arm that literally lends a hand to operators in the manufacturing industry, for example to grip and rotate heavy objects. These are cobots (short for collaborative robots).

The other eye-catcher in the lab are the exoskeletons. There are dozens of them. Where cobots work shoulder-to-shoulder with humans, exoskeletons provide a new step in human history: the fusion of man and machine.

Tom Turcksin (AugmentX coordinator): "Exoskeletons are portable harnesses that you can put on like a backpack. The simple models contain mechanical systems with springs. The more sophisticated models work with small motors or other actuators. They usually support the shoulders or the lower back, and sometimes a combination of the two."

Tom uses us as test subjects to demonstrate how an exoskeleton works. In a matter of minutes, the thing is buckled up. Stepping and moving is a bit stiff at first - a bit like Robocop in the film of the same name - but we soon get used to it. Tom asks us to lift some cardboard boxes off the ground and place them on a table. Bending forward, we feel how the exoskeleton slows the downward movement and supports the lower back. Our dormant sciatica thanks us! What do all such exoskeletons come in handy for?

Tom Turcksin: "In all tasks where employees have to work in a difficult, ergonomically stressful position for long periods of time. With their arms forward, for example. We worked with a dairy farmer who had to connect a milking robot to the teats of his cows. That doesn't sound bad, but it starts to weigh on when you have a few hundred cows and have to perform that same movement every day for 40 years..."

Another taxing position is with the arms high above the head. Professor Tom Verstraten (BruBotics VUB research group): "Think of operators working on the underside of cars, in a factory or a garage. Craftsmen can also benefit from an exoskeleton that supports the shoulders and upper back. A painter who has to paint ceilings all day, for example, or a joiner who drills holes and screws in above his head. In turn, an exoskeleton that spares the lower back is aimed at people who stand bent over for long periods, such as cobblestone and tile layers, band workers, surgeons or people harvesting fruit or vegetables."

In the beginning, exoskeletons were mainly made by startups. Today, major industrial players have also jumped into the market. A model with motors that cost 40,000 a few years ago is now available for 10,000 euros. The cheapest types sell for less than 1,000 euros.

Tom Verstraten: "More and more is becoming possible and affordable, but at the same time not so much is known about how these wearable robotics interact with people. Especially as new brands and models are rapidly emerging. The question is: does each type do what it claims to do? Exactly what forces are transferred? What is the effect on muscles and joints? We investigate all this in our lab."

The laboratory has acquired just about every brand and type of exoskeleton in recent years. The task now is to measure their characteristics and introduce this knowledge into ergonomic analysis. In the field of ergonomic evaluation, AugmentX offers unique services.

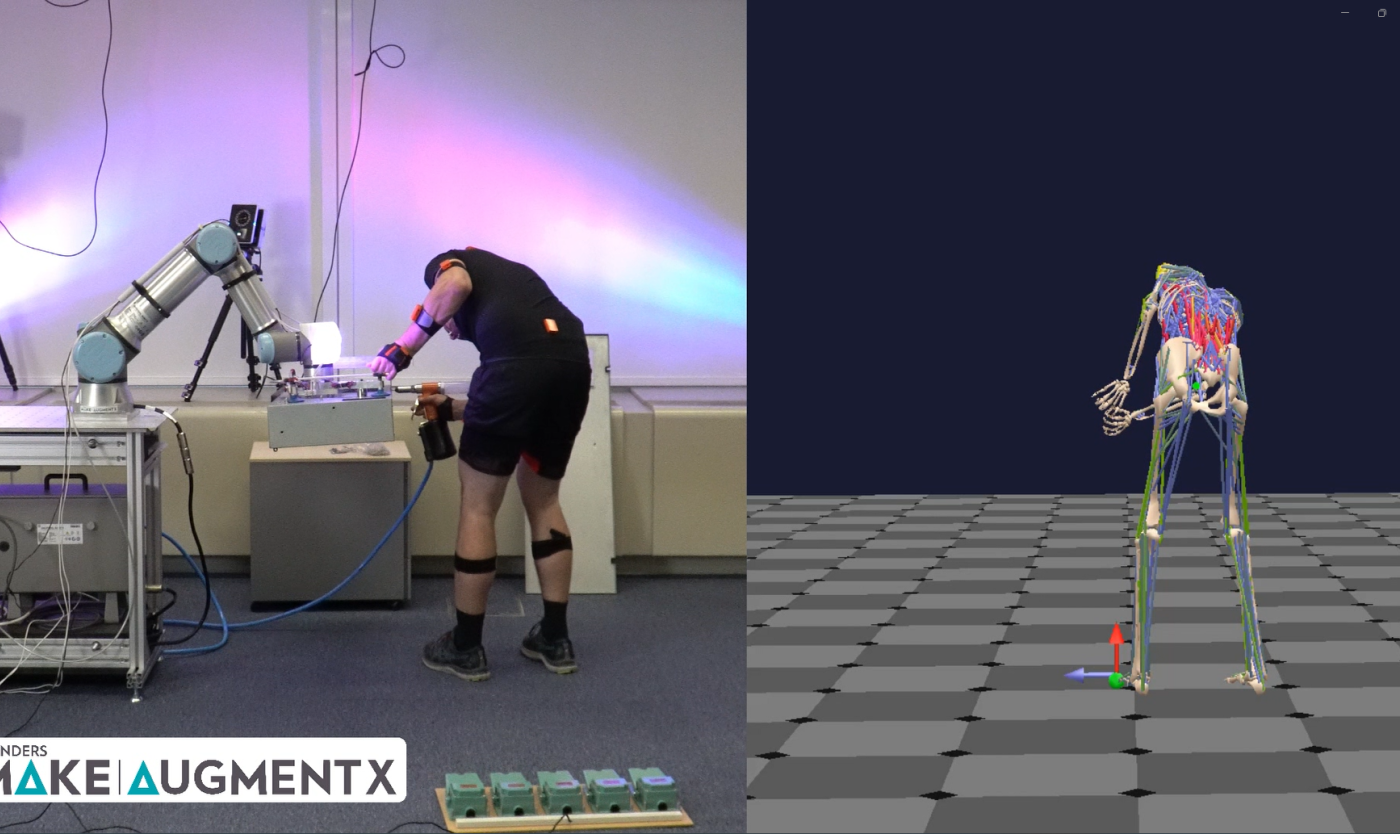

Tom Turcksin: "Thanks to our synchronised measurement system, we can bring together three types of measurements. These measurements are linked to a biomechanical model, say a digital twin of a human being. This model calculates which force is exerted by the many hundreds of muscles in our body. We also measure physiological data to get an idea of the effort exerted. At the end, we have a very accurate picture of how taxing a particular task is for the body."

Tom Verstraten: "The insights we gain in AugmentX give Brubotics and Flanders Make a huge advantage over other research centres. We are also happy to channel this knowledge into spinoffs.”

AugmentX also shares the acquired knowledge with external parties. Companies keen to introduce exoskeletons or other robotics into their production are welcome to attend workshops. They can also borrow and test pilot models, with guidance and follow-up by the lab. Ergonomics experts, prevention advisers or trade union staff can also come to AugmentX for explanations and information.

Tom Turcksin: "We do the ergonomic analyses not only in our lab, but also on site, on the shop floor of a company that asks for them. That is quite unique. Of course, the results are then somewhat less accurate than in a laboratory environment, but they are true to life and completely applied to the situation and needs there."

Tom Verstraten: "We think that exoskeletons, in particular, will now quickly gain acceptance because they are becoming more and more affordable. A cobot quickly costs several tens of thousands of euros - a lot of money for a small company. As an entrepreneur, you then want to be sure that the investment is worthwhile. We can also help in that decision-making process."

Tom Turcksin: "Recently, as a test case, we installed and tested a robotic arm at the customisation company Bewel. Among other things, the employees there have to prepare a series of electrical boxes: inserting rivets, applying mousse, sticking stickers, attaching a door, etc. This is normally all done manually, whereas such a box is not so easy to handle. We programmed a cobot that acts as a 'third hand', holding the box with magnets and suction cups and rotating it. Via sensors on a test subject, we also mapped all movements, forces and physiological parameters here. The info the company gets from such a test session helps decide whether buying such a cobot is worthwhile or not."

The AugmentX lab opens its doors on Thursday 11 January 2024: www.flandersmake.be/nl/evenementen/opening-augmentx-labo (AugmentX@flandersmake.be)

FlandersMake AugmentX and Brubotics

The Flanders Make AugmentX research lab, operated by the Brubotics research group at the VUB, will open its doors. This knowledge centre offers tools and methods to analyse workplaces and optimise the division of tasks between operator and cobots. In addition, AugmentX quantifies the extent to which human-robot collaboration and the introduction of new technologies can reduce physical workloads.

AugmentX is a Flanders Make initiative consisting of a high-precision research lab in Brussels (VUB) and an industrial lab in Kortrijk. The AugmentX lab at the VUB received €1 million from Flanders Make to develop its operation.