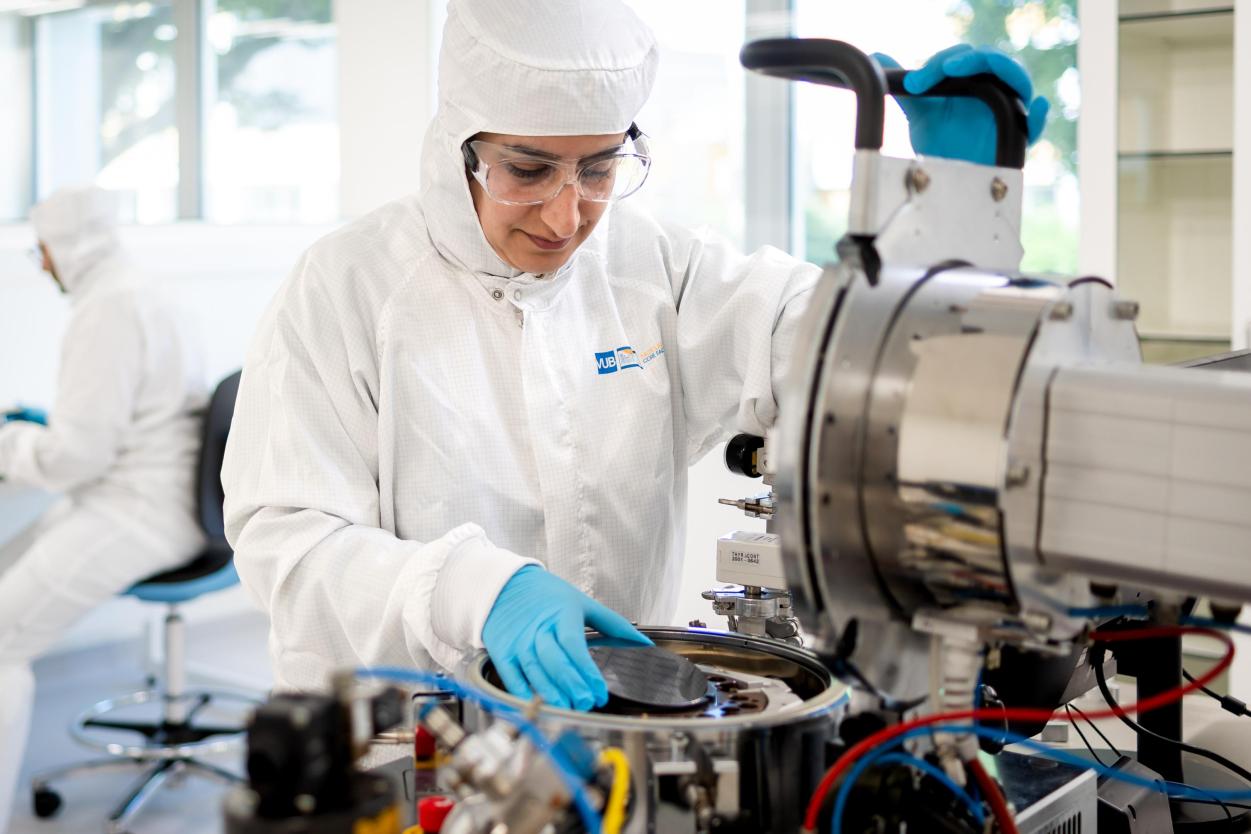

In the former student halls designed by Willy Van Der Meeren, VUB adds a sparkling jewel to its technological crown: the MICROLAB. This brand-new cleanroom borrows techniques from computer chip production to etch liquid chips. Particularly the experiments with glass – as an alternative to silicon – are cutting-edge science. “Eventually, we want to integrate these microfluidic chips into medical testing devices,” explains Professor Wim De Malsche. “A single drop of blood or urine could deliver more precise information than current tests.”

A fingertip prick, a test strip and a glucose meter: that’s all a person with diabetes needs for a daily blood sugar check at home. Yet every three months, they still need to visit the hospital for a more thorough blood sugar analysis. This is done via an HPLC test (a form of liquid chromatography) on a blood sample. It’s sophisticated and time-consuming lab work – and less precise than doctors would like.

Wim De Malsche (Head of the µFlow Research Group and Director of MICROLAB) and Filip Legein (Business Development MICROLAB)

Filip Legein (Business Development MICROLAB): “An HPLC test gives information on glucose and on haemoglobin bound to glucose. The problem is: people of African, Mediterranean or Southeast Asian origin – about 7% of the world’s population – often carry a genetic variant of haemoglobin. This can behave differently in the test and lead to misinterpretation. So for some ethnic groups, the test is less reliable. For women with diabetes, doctors must also be cautious: hormonal differences and body composition can influence the results too.”

“We are replacing bulky lab machines with pocket-sized tests”

At MICROLAB, researchers are working on a more reliable alternative to the HPLC test, based on a microfluidic chip. A liquid chip looks much like an electronic microchip, with similar etched channel patterns – but instead of electric currents, it channels liquids such as blood.

Prof. Wim De Malsche (Head of the µFlow research group and Director MICROLAB): “The channels in a liquid chip are so tiny that fascinating phenomena emerge. If you send a drop of blood through a certain channel structure, you can separate proteins. Place that chip in a small device, and you have a test that measures, for instance, the long-term glucose values of a diabetes patient. Such a test would be more accurate than today’s HPLC analysis.”

Filip Legein: “Microfluidic devices will be smaller and far more practical. The bulky hospital lab equipment will be replaced by a simple DIY pocket-sized test – at the GP’s office or even at home. Think of the Covid test. That’s what we call point-of-care diagnostics.”

Diabetes is just one of many conditions where liquid chips can make a difference. To study Alzheimer’s disease, the research group uses them to create and examine protein condensates – the clumps that settle in the brain during the disease.

Filip Legein: “We’re also looking at organoids: lab-grown mini-livers, kidneys, brains and other organs just a few millimetres in size, used to test different types of medication. In the future, liquid chips could also detect tumour cells in blood or urine, offering an alternative to the classic biopsy.”

“Liquid chips in glass don’t interact with the fluids flowing through them”

Liquid chips can only be built in a cleanroom, with air filtration, anti-static precautions and special suits for staff. A single speck of dust can ruin the final result. At 300 m², the MICROLAB is a generously sized cleanroom packed with high-tech equipment for etching chips.

Wim De Malsche: “I sometimes say we ‘misuse’ the processes for making electronic microchips to build liquid chips. We apply similar dry and wet etching techniques. The main difference is that our channels need to go deeper – tens to hundreds of micrometres. Their walls must also be perfectly vertical, their corners perfectly square. Not 88°, but exactly 90°. That precision is crucial for the chip’s performance.”

Etching processes for microfluidic silicon chips are already established and used by many research groups. What sets MICROLAB apart is its focus on another material alongside silicon: glass.

Filip Legein: “That’s what makes us unique. In Europe, there are only a handful of other places with the infrastructure to produce liquid chips in glass. However, a great deal of fundamental research is still needed to fine-tune these processes.”

Wim De Malsche: “Glass is the material of choice in the chemical and biochemical world because it is usually inert and stable. For medical diagnostics, it’s also very practical — you can see straight through it, whether with the naked eye or using optical equipment.”

Another technique being refined at MICROLAB is acoustic separation. By sending specific sound vibrations through the fluid in a chip, particles can be separated continuously, based on size or other properties.

“We’ve already completed two successful projects with pharmaceutical companies”

Wim De Malsche: “This technique is useful in drug production. We’ve completed two successful projects with pharmaceutical partners. In one, a company wanted to separate large crystals from small ones – the large ones are undesirable in powdered medicines. In another, we were asked to extract yeasts and other microorganisms, used in vaccine production, without damaging them. Filters can’t do that – they would destroy the microorganisms. Acoustic separation works.”

For acoustic separation, the chip channels again need extreme precision, says Wim: “For example, if we use a 2 Megahertz ultrasonic actuator to create vibrations, the channels must be exactly 375 micrometres wide and deep, with perfectly vertical walls. Otherwise, it won’t work. We also want to apply this technique to glass. These are very challenging developments – they involve entirely new processes.”

The idea for a cleanroom arose just four years ago. That MICROLAB is already up and running borders on miraculous, considering the huge investments in high-tech infrastructure and the steep costs involved.

Wim De Malsche: “The university has given us outstanding support, and we’ve been fortunate with Flemish, federal and European grants, both for infrastructure and for research projects. VUB is very strong in this field – it should be said. Especially since our team combines so many areas of expertise.”

Filip Legein: “MICROLAB is one of the first core facilities at VUB: we bring together infrastructure that all researchers at the university can use. Financially, that’s far more effective than everyone working in isolation. Researchers from other universities and companies are also welcome, provided they follow training and pay a usage fee. Applications are already coming in. The ambition is to become self-sustaining in the long run.”