3D-printed aircraft components and self-healing polymers for robots: just two of the hot topics keeping Guy Van Assche and Iris De Graeve busy in the SUME (Sustainable Materials Engineering) research group. We meet them in their brand-new offices and laboratories on the ninth floor of VUB’s G-building, a project co-funded by the European Union and the Brussels Capital Region as part of the ERDF (European Regional Development Fund) program.

Flying ten kilometres above the ocean, you’d rather not think about it: the metal parts of an aircraft can fail because they are exposed to natural forces and chemical agents. The polymer coatings that protect the metal from corrosion also lose performance over time.

Professor Guy Van Assche: “The outer parts of aircraft are exposed to de-icing chemicals, the inner parts to condensation. To understand the consequences, you need to grasp both the polymers and the underlying metals, as well as the corrosion phenomena. That requires close collaboration between two labs within SUME: the Physical Chemistry and Polymers lab, where I am a research leader, and the Electrochemical and Surface Engineering lab, where Iris De Graeve leads research. We often join forces on projects for aerospace companies.”

Professor Iris De Graeve: “An aircraft is expected to last around thirty years. We work to fully understand corrosion processes. Based on that knowledge, we build future models of how metals and polymers evolve under changing weather conditions. Our modelling team has been producing complex short-term simulations for many years. To predict corrosion over the long term, we increasingly use machine learning and AI.”

“The weak spot of 3D-printed metals is the surface”

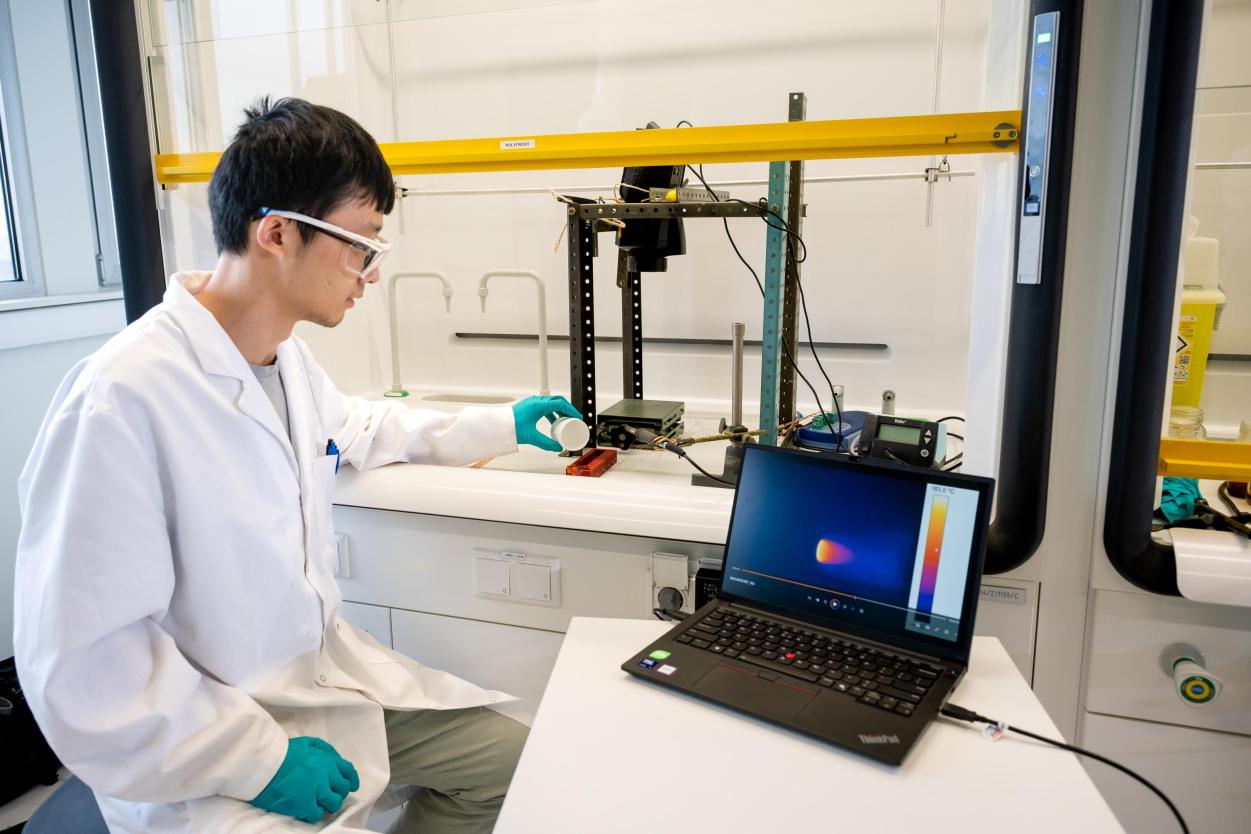

A hot topic in the Electrochemical and Surface Engineering lab is 3D-printed metals. Created from metal powders or wire, they are used in machine building, biomedical applications, and especially in transport — including car and aircraft components.

Iris De Graeve: “In aviation, every hundred grams counts: the lighter the aircraft, the lower the fuel consumption. A part that would normally be assembled from several pieces can be printed in one. With optimised design, the printed part can even be made lighter, while still being just as strong. But printed metals behave differently to conventionally assembled ones. In our lab, we investigate how this affects corrosion and metal fatigue.”

These 3D-printed metals are not yet perfect. Their microstructures are new and lead to very different behaviours compared to traditional components. Their weakest spot is the surface. Often it comes out too rough, with unmelted metal particles or fracture-prone spots caused by residual stress.

Iris De Graeve: “That depends on the material and the printing technology used. We’re working on how to improve this. For example, we studied a 3D-printed part designed to be fixed under the wing of an aircraft — a component normally assembled from ten separate pieces. This was done at the request of Belgian aerospace company SABCA, within a Brussels Innoviris project.”

“A robot pricked by a thorn will heal itself”

In the Physical Chemistry and Polymers lab, the focus is on developing self-healing polymers. Together with Professor Bram Vanderborght of BruBotics, the Brussels Human Robotics Research Centre, these materials are being tested for use in soft robots that interact with humans and nature.

Guy Van Assche: “Bram asked us to develop a polymer that could heal itself for use in the soft parts of robots. Until then, we mainly worked with harder, self-healing polymers. Scratches or cracks in those could only be repaired by heating the material. Now we’ve developed soft, elastic polymers — rubber-like materials — that can heal at room temperature. Their molecular network contains reversible bonds — weak links, if you like. When you cut the material, those weak bonds break. Push the two parts back together and the bonds reconnect. In other words: the material heals itself.”

That’s handy for the pneumatic finger of a robot. Cut it, press the pieces together, and minutes later it can move again as one. After seven days, the strength curve is identical to the original: the polymer is fully healed and just as strong.

Guy Van Assche: “Think of a robot in fruit farming, picking raspberries or blackberries. Its pneumatic hand must be soft enough not to bruise the fruit, but still handle thorns. You don’t want the hand’s air chambers to get damaged each time. With these polymers, any puncture closes up on its own. The same goes for microcracks from repeated bending and stretching. Over time, the damage heals itself. Together with Bram, we’re working to commercialise these soft polymers through the spin-off Valence Technologies.”

“Thanks to carbon black, robots can feel”

The researchers have gone a step further. By adding carbon black to the robot polymers, they’ve made the material sensory — able to ‘feel’.

Guy Van Assche: “Carbon black is a black powder made almost entirely of carbon. It’s used in car tyres to make the rubber stronger. We use a different property: our composites of soft polymers and carbon black conduct electricity. When the material stretches or deforms, its electrical resistance changes. You can measure that easily with a multimeter at the ends of the composite strip. Built into a robot finger, the strip stretches as the finger bends, changing resistance. The meter reads it out, and the robot knows exactly how far its finger has bent.”

Damage to the sensor? The robot feels that too. Thanks to the self-healing polymers, even the sensors repair themselves when damaged. The next goal for Valence Technologies: self-healing tyres. Now that’s what you call a market opportunity.

A peek inside the labs of VUB scientists?

Join us on 23 September 2025 for the Academic Opening and explore the renewed VUB laboratories

On 23 September, VUB will not only open the new academic year but also the doors of its laboratories. Discover live the technological innovations and scientific breakthroughs our researchers are working on – the very ones that could soon make the headlines.